Portal frame: The core solution for light steel structures - an efficient, economical, flexible and versatile modern building system

Release time:

2025-07-17

I. Definition and Origin

Portal frame light house (referred to as portal frame) is a single-story steel structure with portal frame as the main load-bearing structure and equipped with a light enclosure system. It can carry bridge cranes with a capacity of ≤20 tons or suspended cranes with a capacity of 3 tons, and is suitable for working levels A1 to A5. This system originated in the United States and, after a century of development, has formed a mature technical system for standardized design, production and construction.

Ii. Structural System Analysis

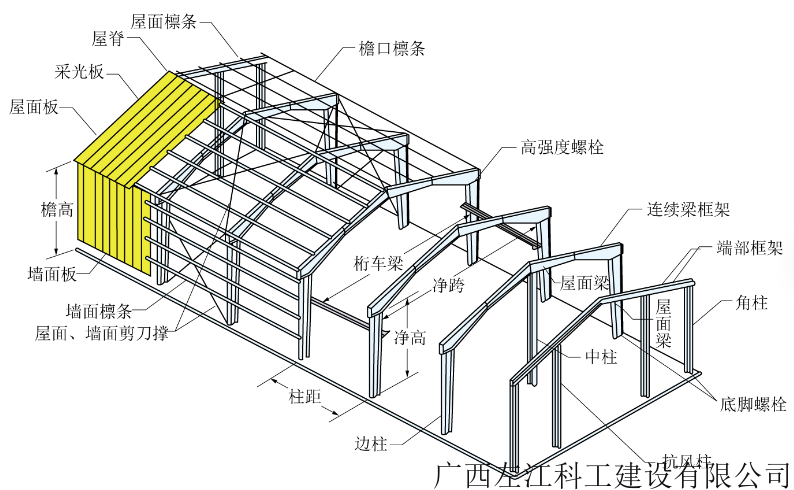

1. Main structural system

- Portal frame: Core load-bearing unit, featuring a welded solid web I-shaped cross-section, including inclined beam and column components. It is available in two types: clear span without inner columns and multi-span with inner columns, to meet different span requirements.

- Crane girder system: Specifically designed for crane loads, it enables force transmission to the column.

- Support system: The roof and inter-column supports form an anti-lateral force system to ensure longitudinal stability.

2. Sub-structural system

- Purlin/Wall beam: C/ Z-shaped thin-walled steel frame, integrated enclosure structure and load-bearing function.

- Tie system: A key component for enhancing the integrity of the secondary structure.

3. Enclosure system

Profiled steel sheets (single plates/composite plates) achieve the integration of waterproofing, insulation and decoration. The load transmission path: panel → purlin → main structure.

4. Basic System

Hinged/rigidly connected reinforced concrete independent foundations, suitable for different geological conditions and deformation requirements.

Iii. Core Advantages

| Advantage dimension | Technical performance | Economic benefits |

| Construction efficiency | Factory prefabrication and on-site assembly, 5,000 to 10,000 square meters projects can be delivered within three months | Shorten the capital recovery cycle by more than 30% |

| Spatial value | The maximum span can reach 60 meters, and the space utilization rate is increased by 20% |

Reduce the cost per unit area by 15% |

|

Material properties |

Its self-weight is only one third of that of concrete structures and it has excellent seismic performance |

The basic cost is saved by 25% |

| Sustainability | The steel recovery rate exceeds 90%, and it is equipped with environmentally friendly building materials | The full life cycle cost was reduced by 18% |

Iv. Typical Application Scenarios

- Industrial field: Mechanical factories, logistics and warehousing (suitable for 5-20t crane working conditions)

- Business sector: Large shopping malls, agricultural and sideline products wholesale markets (model of rapid construction)

- Public buildings: Sports venues, exhibition centers (large space solutions)

V. Key Technical Control Points

1. Design stage

- Load combination optimization: It is necessary to take into account special working conditions such as wind pressure, snow load, and dynamic load of cranes

- Fine node design: Adopting a hybrid connection technology of friction-type high-strength bolts and welding

2. Construction stage

- Foundation embedding accuracy control: Allowable deviation ≤3mm

- Component hoisting sequence: Follow the principle of "column → beam → support → secondary structure"

Vi. Industry Development Trends

1. Intelligent upgrade: BIM forward design + application of robot welding technology

2. Green Deepening: Research and Development of photovoltaic Integrated Roofing systems

3. Modular expansion: Detachable and reconfigurable structure technology

As a benchmark system of modern light steel structures, portal frames continuously drive the technological revolution of "fast construction" and "low-carbon buildings". Through the perfect combination of standardization and customization, it is redefining the cost-performance boundaries of industrial buildings and has become the preferred solution for upgrading industrial infrastructure.

Guangxi Zuojiang Kegong Construction Co., Ltd. provides design drawings, offers free drawing deepening services, and undertakes various steel structure factory building projects and sports venue grid structure projects. Welcome to visit our factory. Factory address: No. 59, Airport Avenue, Fusu Economic Zone, Nanning Airport, China-Asean